Shippingport & LWBR

Overview

On December 8, 1953 President Dwight D. Eisenhower went before the United National General Assembly to propose an “Atoms For Peace” plan. One of the cornerstones of the plans for the peaceful uses of atomic energy was the building of a nuclear power plant for the commercial generation of electricity to be used as part of a utility system. Thus the congressional Joint Committee on Atomic Energy and the Atomic Energy Commission developed plans for an atomic power station.

A large-scale light water reactor for a proposed aircraft carrier was then being designed at Westinghouse Electric Corporation’s Bettis Atomic Power Laboratory under the technical direction and in cooperation with the Division of Naval Reactors of the Atomic Energy Commission. However, in April 1953, the AEC proposed canceling the plans for the aircraft carrier and redirect the funds into a civilian reactor for electric power production. The AEC notified the electric utility industry that they were accepting bids from utilities with the proposal that the utility participate in building and operating a full-scale atomic power station as part of its generating system. The principal responsibility for carrying the civilian reactor plant project to a successful conclusion was given by the AEC to the AEC Division of Naval Reactors led by then Rear Admiral H. G. Rickover.

With a bid that included supplying the land, the turbine generator and $5 million toward the research and development of the light water reactor, Duquesne Light Company was chosen in December 1954 as the utility for the project. The land was located in the small village of Shippingport, Pennsylvania on the Ohio River about 25 miles from Pittsburgh.

Shippingport, unsurprisingly, shared many characteristics with the naval plants under design and construction, but incorporated many new and different features also. In this design, as in the naval plants, Rickover showed his immense talent for correct decisions. The design philosophy emphasized safety, design conservatism, reliability, and the redundancy needed for good availability.

In addition, the Shippingport project was directed towards advancing the basic technology of light water cooled reactors, through design, development, building and testing and operation of a large power reactor as part of a public utility system. Because of this primary mission, the design of the station is markedly influenced by its dual role of test facility and power producer. The test facility concept results in a duplication and isolation of equipment and in a large amount of instrumentation compared to that required solely for operation as a power producer.

The Shippingport station was constructed for the purpose of advancing nuclear power technology generally. Accordingly, the entire plant was built along very flexible lines. The reactor portion could accommodate cores of different types, and greater power. Multiple components were made by a number of manufacturers using different designs and materials of various kinds were utilized.

It was a pressurized water reactor (PWR) which incorporated the principle of layers of defense against the release of radioactivity and fission products in accident situations, recognizing the loss of coolant accident as the one causing greatest consequence for a PWR. It would be a 4 loop. plant, albeit full power could be achieved with only 3.

Submarine reactors needed and could justify very expensive highly enriched fuel, to achieve a small reactor plant. For a civil plant, pressure vessel size did not create a constraint, low cost rather than small size was the driving feature. A novel "seed and blanket" design was decided upon, in which the seed would be highly enriched fuel. as for naval plants, and the blanket would be natural uranium. Existing knowledge favored uranium- molybdenum alloy, but Rickover opted for the lesser known alternative of uranium dioxide in zircalloy cans. This inspired choice proved so successful that it became widely used in the civil power industry.

The ground breaking ceremony on September 6, 1954 (Labor Day) was attended by about 1,400 people, including dignitaries representing nations from around the world. President Dwight D. Eisenhower, the father of the “Atoms For Peace” program, participated in the ceremony via an electric hookup from a summer White House in Denver, Colorado.

While construction started, the core was being designed and built. The first core was an assembly of plates and rods arranged in the general shape of a cylinder, 6 feet high and 7 feet in diameter. The plates in the first core were enriched uranium clad with an alloy of zirconium as protection from the hot water; the rods were hollow zirconium alloy tubes filled with natural uranium oxide pellets. The core was a seed and blanket type with the enriched uranium plates constituting the seed and natural-uranium rods the blanket. The reactor contained enough fissionable fuel to form a critical mass: one capable of sustaining a nuclear chain reaction. The chain reaction could be started, stopped and controlled by 32 neutron absorbing control rods made of the element hafnium. When inserted into the reactor, the control rods slowed the chain reaction (less reactivity) and lowered the power level: when withdrawn, they allowed the chain reaction to increase (more reactivity) and power to increase. Power could be maintained constant thanks to a negative temperature coefficient of reactivity such that the reactor inherently tended to maintain the power level at which it was set. If, for example, the temperature of the water entering the reactor dropped for any reason, the reactor automatically produced more heat, and thus a higher outlet water temperature. If the inlet water increased in temperature, the heat output of the reactor automatically dropped. Thus, the reactor itself automatically maintained the correct power level with no controls being involved.

The seed-and-blanket core used a relatively small amount of enriched uranium and a large amount of natural uranium. A metallic alloy of enriched uranium (-93% U-235) in the form of plates was contained in 32 assemblies collectively called the "seed", while the natural uranium was contained in 113 stacks of assemblies collectively called the 'blanket". The fuel in the blanket region was natural uranium in the form of U02 pellets clad in 10.25-inch-long Zircaloy-2 tubes. Seed assemblies were arranged in a square annular array with blanket assemblies both inside (45) and outside (68). Thus a core was produced in which neutrons leaking from the highly enriched seed caused plutonium production and fission in the plutonium and natural uranium of the blanket assemblies. The seed fuel contained approximately 165 pounds of U- 235. The blanket was made up of 14.2 tons of natural uranium in the form of uranium dioxide. The water-cooled natural uranium could not by itself sustain a chain reaction. Furthermore, the seed assemblies alone in their square annular array, even in the presence of water and without their control rods, could not by themselves sustain a chain reaction. The neutron multiplying and reflecting characteristics of at least a portion of blanket material were required to sustain the chain reaction.

After more than four years of planning, construction, testing and plenty of plain hard work, the Shippingport reactor was ready for fuel loading. In October, 1957 the reactor core weighing 58 tons and containing 14 tons of natural uranium and 165 pounds of highly-enriched uranium was installed. A little more than 45 days later the plant was ready for operation. At 4:30 a.m. on December 2, 1957, the control rods were raised just to the point of criticality, where the atomic reaction would maintain itself. This historic milestone for Shippingport also coincided with the 15th Anniversary of the World’s first nuclear fission reactor which was built under the football stadium at The University of Chicago by a group of scientists headed by Enrico Fermi.

On Wednesday, December 18, 1957 at 12:30 a.m. the first power was produced at Shippingport Atomic Power Station as engineers synchronized the plant with the Duquesne Light Company system. Thus the first electricity to be generated at Shippingport was fed into the grid that carried electricity throughout the Pittsburgh area. Within a few days, on December 23, 1957, full power of 68,000 kilowatts was attained by the Shippingport reactor.

The blanket fuel for the first Shippingport PWR core was bulk U02 in the form of cylindrical pellets. The second core used this ceramic material in plate shapes to take advantage of greater heat transfer area and lower fuel temperatures. This was coupled with the development of Zircaloy-4 as a long-life cladding material. The compartmented oxide plate fuel element, developed for both the seed and blanket, was especially suitable for meeting the higher power density, higher total energy, self-shielded boron burnable poison, and zoned fuel loading requirements of the second core. The second seed-blanket core for Shippingport consisted, as did the first core, of a relatively small, annular-shaped seed region (-21% of core volume) surrounded on the inside and outside by blanket regions. The seed fuel was highly enriched U02 diluted with Zr02 or ZrO2-CaO,contrasted with the uranium-Zircaloy alloy of Core 1. From the standpoint of neutron regeneration, the seed was self-sustaining, while the blanket was not. Accordingly, the seed was the reactivity controlling region and control rods were required only in the seed. The seed had 20 assemblies, each containing a hafnium cruciform control rod; the blanket had 77 assemblies. The seed and blanket assemblies extended the full 8-foot height of the reactor.

During the life of the first core (1957-1964), the station produced almost 2 billion kilowatt-hours of electricity. In 1964, the plant was removed to install a second core.

The new core increased the plant’s electrical generating capacity from 60,000 to 100,000 kilowatts. It had more than 5 times the design energy output and over twice the power of the original core. Core #2 was instrumented so that information concerning power distribution in the reactor was available for further improvements and refinements in future nuclear power stations.

From February 3, 1965, when the second core went into operation, until February 4, 1974, Shippingport Atomic Power Station generated almost 3½ billion kilowatt hours of electricity.

Starting in 1965, Naval Reactors began development of a Light Water Breeder Reactor (LWBR) Core for use as the third reactor core for refueling of the Shippingport Atomic Power Station. A breeder reactor is one that creates more fissionable nuclear fuel than it consumes. The LWBR used a nuclear fuel material, thorium, that is in plentiful supply and for which, to date, there has been no other major energy-related use. The thorium is used in a type of nuclear reactor core that can be operated in pressurized light water nuclear power plants. The operation of the LWBR Core in the Shippingport Atomic Power Station was intended to confirm that breeding can be achieved in a pressurized light water reactor using the thorium/uranium-233 fuel system in a seed-blanket core configuration. This reactor was designed to breed more new uranium-233 from thorium than it consumes while producing electrical energy. This means that once on the breeding cycle, an LWBR replacement core could be produced without requiring further mining or enrichment of uranium ore.

The LWBR core contained 12 hexagonal-shaped modules arranged in a symmetric array surrounded by 15 reflector modules. Each of the hexagonal fuel modules was composed of a central movable seed assembly surrounded by a stationary blanket assembly. The movable seed assemblies were used instead of control rods or soluble poisons to control reactivity. This minimized parasitic neutron capture and made breeding possible in the core. Fuel was in the form of ceramic pellets sealed within 10-foot-long Zircaloy-4 tubes. Fuel pellets in the seed and blanket assemblies were composed of the mixed oxides of uranium-233 and natural thorium (essentially, one isotope, Th-232). In short sections at the tops and bottoms of the seed and blanket fuel rods, the fuel pellets were ThO2. The reflector region, surrounding the power-producing seed-blanket modules, contained fertile thorium fuel that absorbed escaping neutrons. The capture of neutrons by the thorium produced new fissile uranium-233 fuel. The seed-blanket-reflector configuration of the LWBR core had 17,287 fuel rods containing approximately 1.6 million ThO2-UO2 pellets and 1.3 million ThO2 pellets.

The plant went out of service on February 4, 1974, because of a mechanical failure in the turbine-generator. A decision was made to begin installation of the LWBR while repairs moved forward on the turbine-generator. Again Shippingport Atomic Power Station was the scene of another of the nation’s first in nuclear technology. The LWBR was brought to initial criticality on August 26, 1977. After undergoing checkout and initial testing, President Jimmy Carter from the Oval Office in the White House, on December 2, 1977 ordered the LWBR to 100% power. The reactor was then released for routine commercial electric power generation.

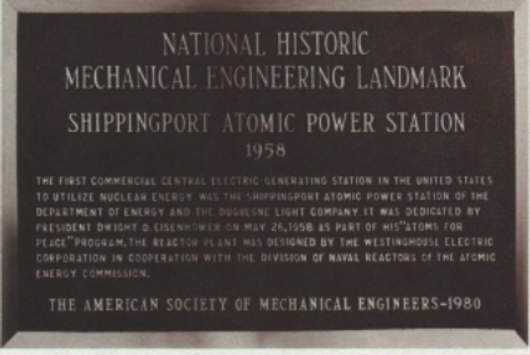

In May 1980, the Shippingport Atomic Power Station was declared a National Historical Mechanical Engineering Landmark by the American Society of Mechanical Engineers.

Shippingport ceased power operation on October 1, 1982 due to the economic inefficiency of the plant relative to new power plants.

After shutdown, the expended core was examined, and no evidence of any fuel element defects was found. Nondestructive assay of 524 fuel rods and destructive analysis of 17 fuel rods determined that 1.39% more fissile fuel was present at the end of core life than at the beginning.thereby establishing that breeding had occurred. Successful LWBR power operation to over 160% of design lifetime demonstrated the performance capability of this fuel system. Detailed results of expended core examinations are available in INEEL/EXT-98-00799 Rev 2 - Fuel Summary Report.

A great movie about Shippingport from 1950's (likely 1958) is available here

This overview does not contain any defense technical information.

Timeline

April 1953 - AEC Decision to pursue commercial nuclear power plant

Dec 1953 - President Eisenhower announces "Atoms for Peace"

Dec 1953 - Duquesne Light Company and Shippingport Site selected

Sep 1954 - Ground breaking

Oct 1957 - Core load

Dec 1957 - Initial Criticality (12/2/1957)

Dec 1957 - 1st Power Produced (12/18/1957)

Dec 1957 - Full Power (12/23/1957)

Feb 1965 - 2nd Core operational

1965 - Design work begins on LWBR

Feb 1974 - Shutdown due to TG failure

Aug 1977 - LWBR Operational

Dec 1977 - LWBR Full Power

References

(1) Shippingport National Historical Mechanical Engineering Landmark Program, May 1980

(2) Detailed LWBR Expended Core Examination Report INEEL/EXT-98-00799 Rev 2 - Fuel Summary Report

(3) Shippingport Operation with LWBR (WAPD-TM-1542), March 1986

(4) The Shippingport Pressurized Water Reactor, Naval Reactors, 1958

(5) Bettis Shippingport Report (1993 WAPD-T-3007), 1993

(6) LWBR Nuclear Design and Performance (WAPD-TM-1326), 1979